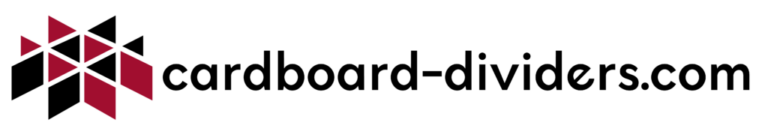

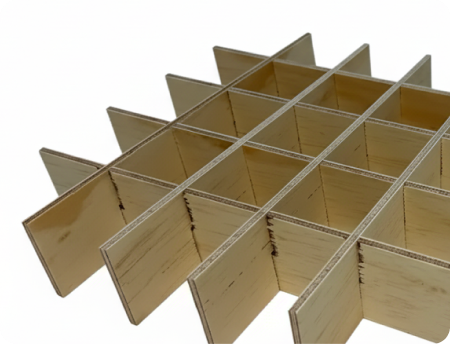

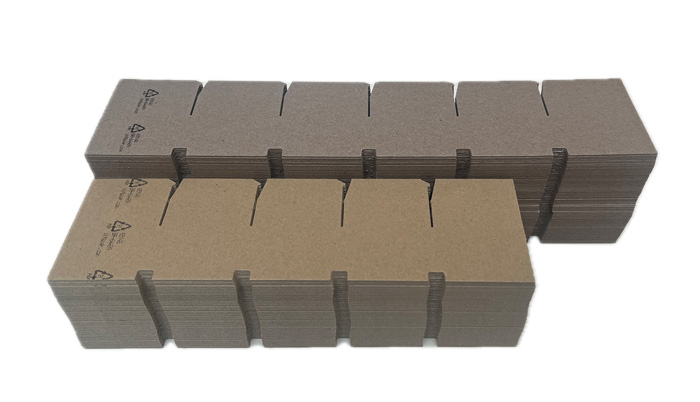

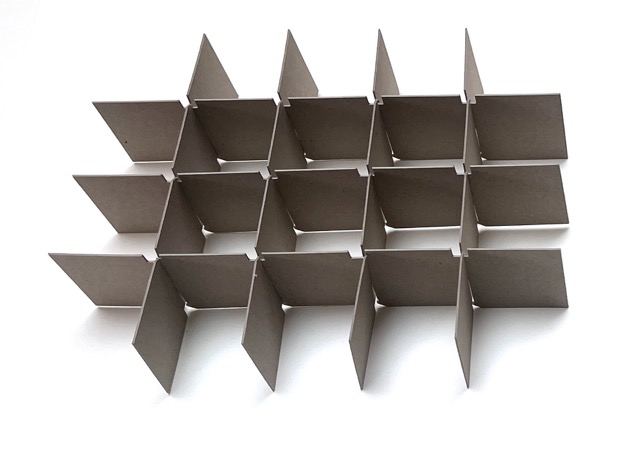

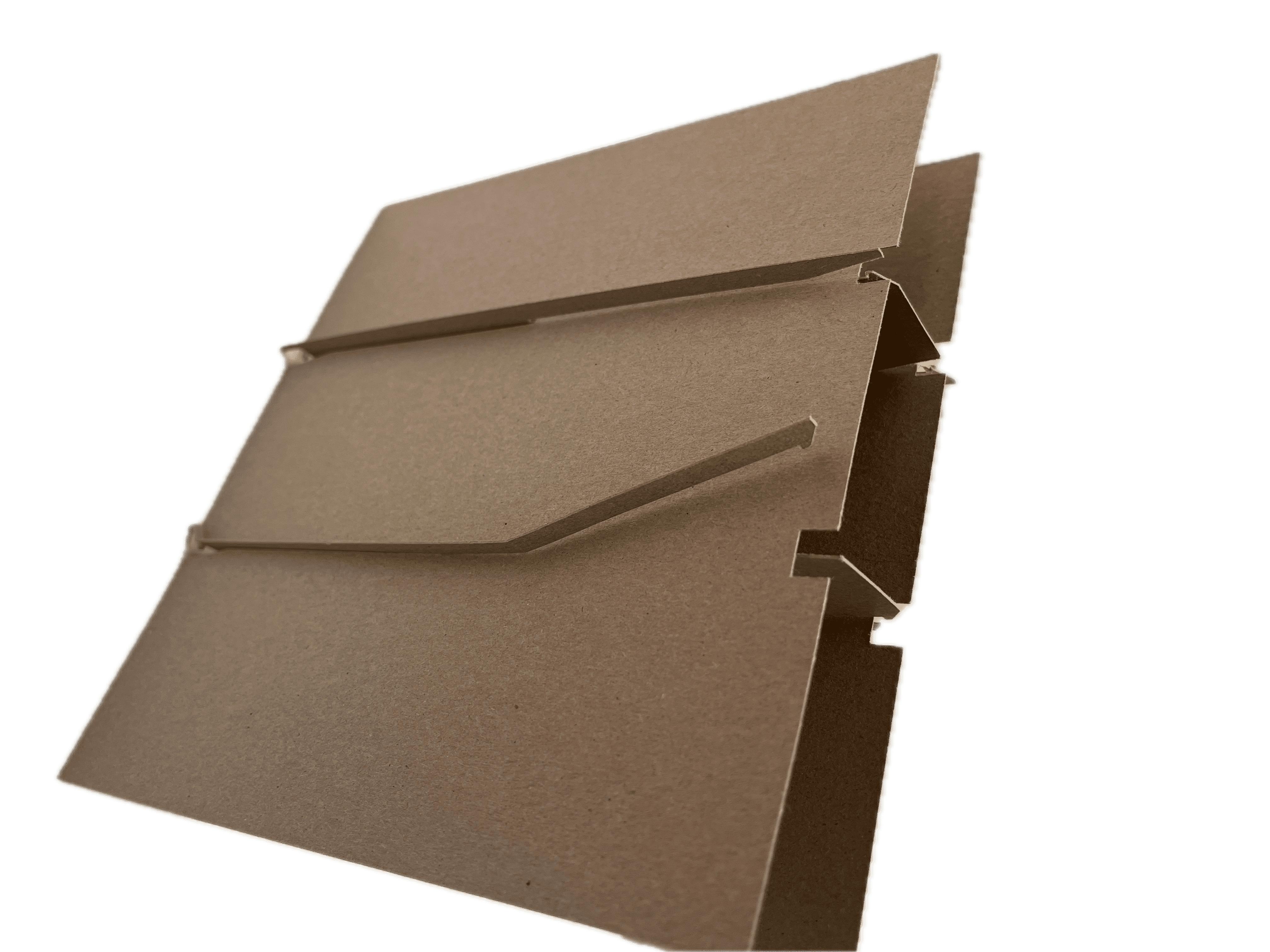

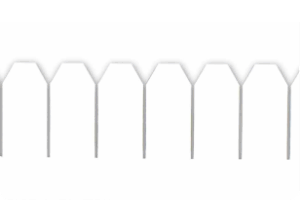

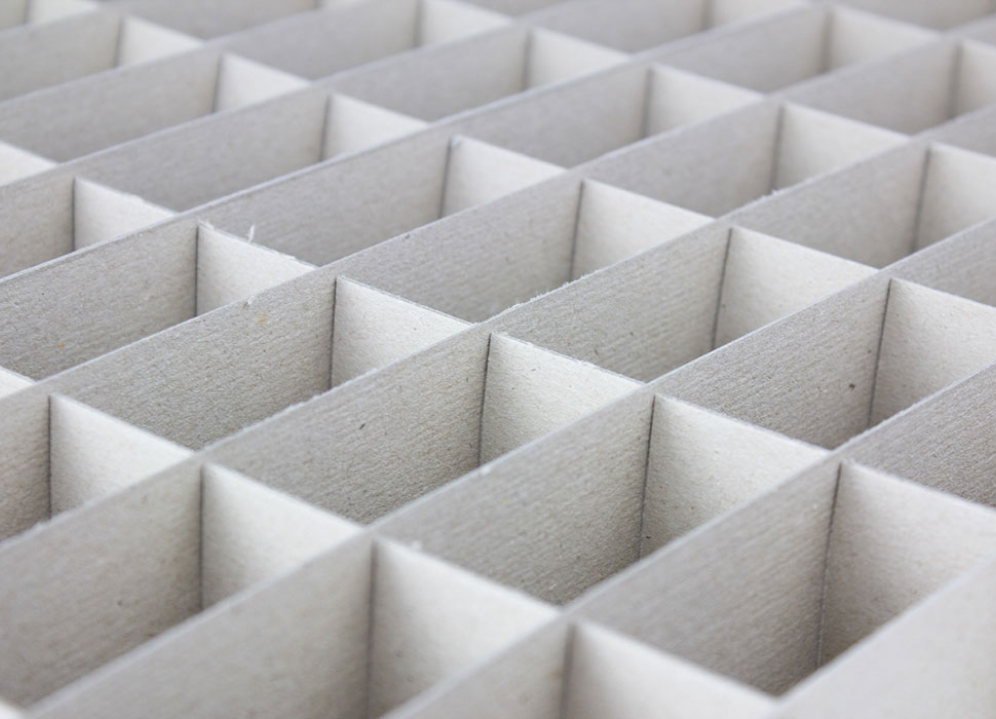

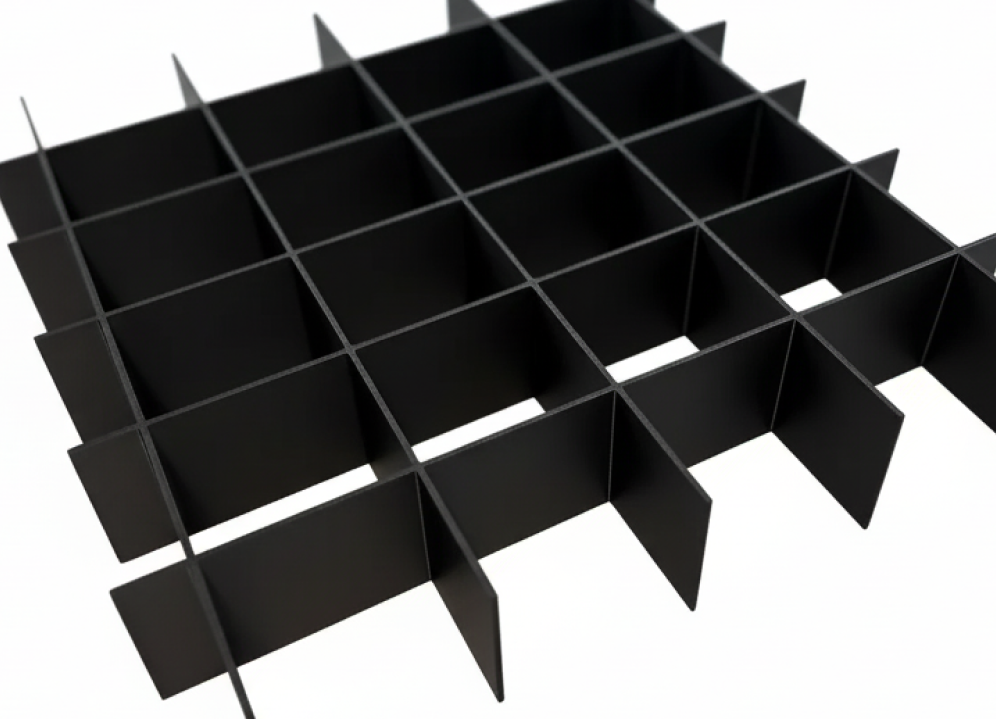

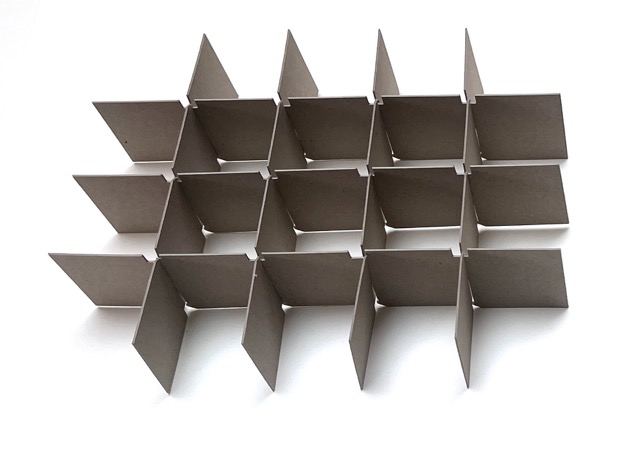

A spacer cell fills the remaining space between the product cells and the packaging, potentially offering additional protection.

Based on your input, we automatically determine whether and on which sides spacer cells need to be added to ensure that your desired cell dimensions are maintained.

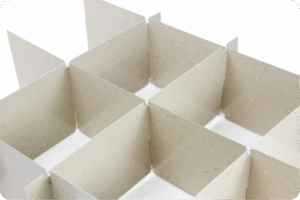

No

Spacer Cells

Spacer Cells along divider length and width

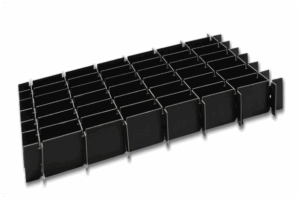

Note:

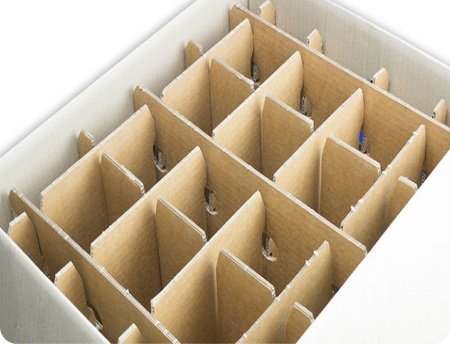

If you manually override our recommendations and choose not to include spacer cells, the individual cells will automatically adjust in size. This may result in cells that no longer fit your product perfectly.

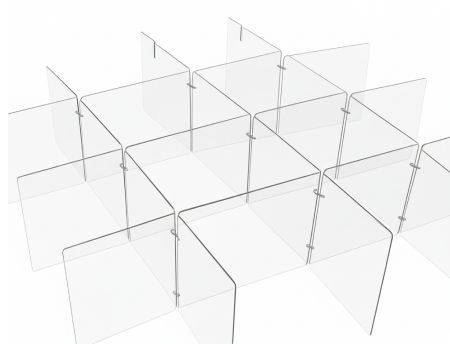

Spacer cells near the divider's edge can break easily, even during delivery, but this may be better than omitting compartments altogether.